Laboratory Facilities

There are various types of laboratory facilities available for Department of Engineering Technologies students to enhance their hands on learning experience.

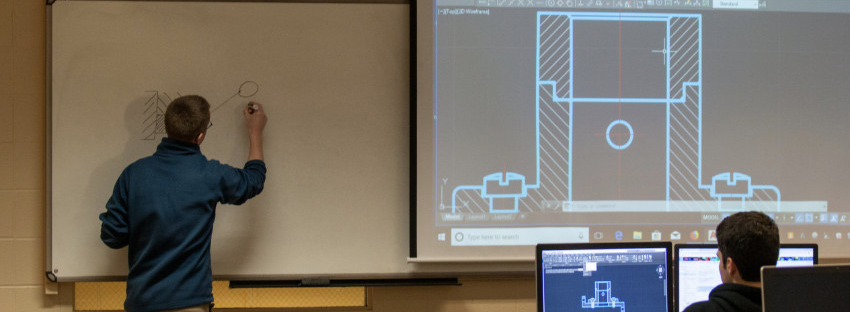

In addition to these labs, there are active learning classrooms accessible for BGSU students. Each of the classrooms has an Extron system and wireless connectivity with varying display technology (e.g., document camera, wall-mounted monitors, multiple instructor monitors, projectors/screens, etc.) and movable table/chair set ups.

Engineering Technologies

FEATURES

- 8,800 square-foot training complex with classrooms and offices

- 8,000 square-foot hangar

- RedBird Full-Motion Simulator and FRASCA Simulator

- Fleet includes:

- Piper Warrior III - 7

- Piper Archer - 2

- Piper Arrow - 2

- Piper Seminole

- Cessna 152

FEATURES

- 30 student workstations

- 24-hour access

- AutoDesk suite available

- Updated with SolidWorks and Mastercam

- Open to all University students

FEATURES

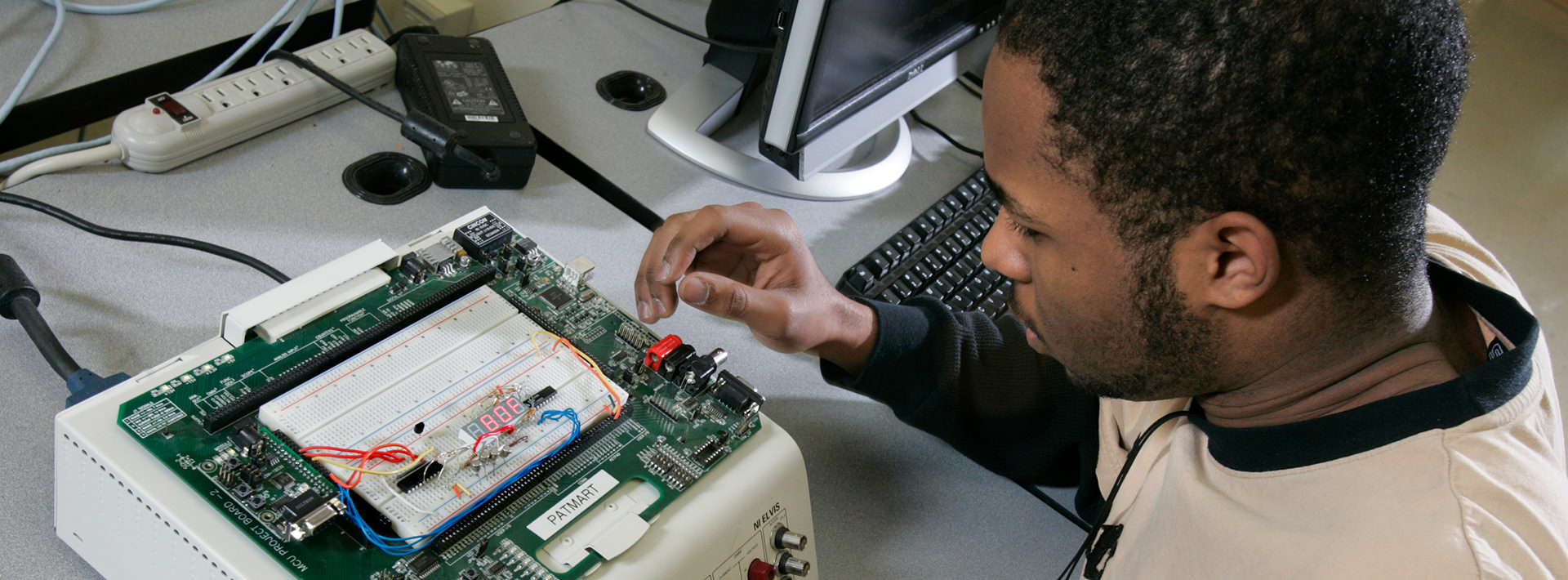

- Instruments and supplies include

- Oscilloscope

- Signal Generator

- Frequency Counter

- Resistors

- Capacitors

- Breadboards

- Soldering Kits

- Multisim software

FEATURES

- Consists of six areas:

- Fluid power

- Metal fabrication

- Casting

- Welding

- Materials properties

- Metrology

- Equipment is available to students working on independent projects

- Instruments and supplies include oscilloscope, signal generator, frequency counter, resistors, capacitors, breadboards, soldering kits, and Multisim software

FEATURES

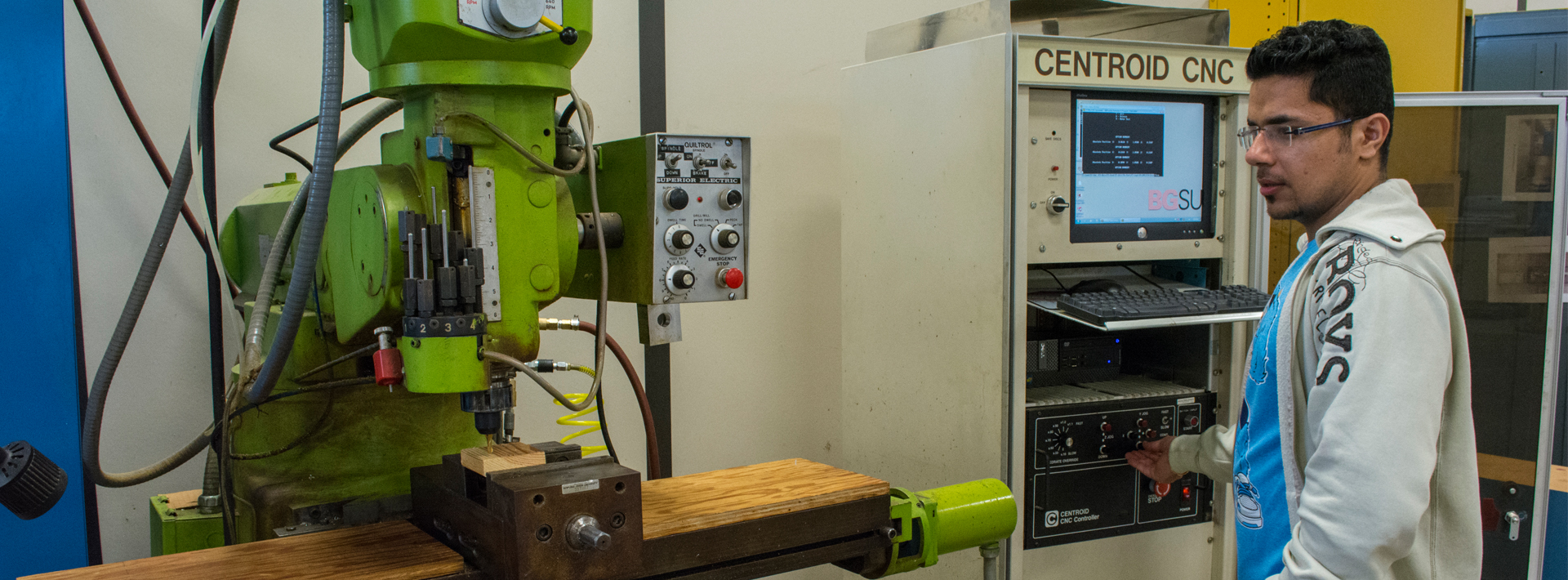

- PLC trainer: 1 Siemens trainer with software and training material

- Computer-integrated manufacturing: 1 CNC integrated with Fanuc robot

- Robotino Mobile Robot: 2 AGVs

- Vision systems: 10 Cognex camera attached to robots with insight software

- Roboguide: 25 seats for Manufacturing Simulation environment

- Automation Studio: 30 seats, Full package

- SCARA Robots: 10 Mitsubishi Robots with programming software

- Teaching Pendants: 10 hand held controllers for Robots

- PLC Automation: 10 integrated control systems with I/O

- Automation Platform: 10 platform with sensors and actuators

- Pneumatic Grippers: 10 integrated hands for assembly operation

- ANSYS, Workbench and Electromagnetic: 50 seats for FEM modeling and simulation

- 20-sim: Unlimited seats for Mechatronics simulation environment

FEATURES

- Ten industrial training robots (SCARA Mitsubishi) integrated with automation and control systems through Ethernet PLCs and CC-link networks.

- Cognex vision systems for quality inspection.

- Electro mechanical and pneumatic Mechatronics systems.

Updated: 01/08/2024 10:13PM