Sculpture and Integrated Studio

All students are welcome to use the Integrated Studio but must receive training with the School of Art Technicians prior to their first use. The studio is comprised of multiple areas which are listed in the tabs below.

Our Sculpture and Integrated studio facilities feature over 12,000 square feet of space divided into 6 different work areas. They include a wood working and assembly area, a metal fabrication area, a CNC fabrication area, the rapid prototyping room, student studio loft, and Outdoor Patio. In support of making, the area is equipped with more than 50 major pieces of powered equipment, a 5-ton bridge crane, and forklift for largescale material constructions.

Hours: Monday - Friday 9am - 5pm

The Woodshop equipment consists of:

- Stop Saw Table Saw

- (3) Bandsaws

- Resaw Bandsaw

- (2) Scroll Saws

- (2) 12 inch Compound Miter Saws

- Panel Saw

- 8 inch Joiner

- 25 inch Planer

- Table Router

- Lathe

- Drill Press

- 20 inch Disc Sander

- Combination Belt and Disc Sander

- Spindle Sander

- 15 inch Drum Sander

- 25 inch Drum Sander

The Rapid Prototyping Room has an array of small CNC machines and other equipment students may use in the creation of their art.

The Rapid Prototyping Room equipment consists of:

- Computer Work-Station

- 80 inch Screen Monitor

- (2) 28 Screen Monitors

- Cannon Large Format Printer

- Graphtech FCX 4000 Plotter/Cutter

- Cricut Machine

- Desktop Vacuform Machine

- Boss Laser Cutter

- Glowforge Laser Cutter

- (8) Creality Ender 3 Pro 3D Printers

- CR Ender 5 Plus 3D Printer

- CR 10 v2 3D Printer

- (2) Creality LD 006 Resin Printers

- (2) Creality UV Machines

- Juki Sewing Machine

- Singer Heavy Duty Sewing Machine

- Dress form

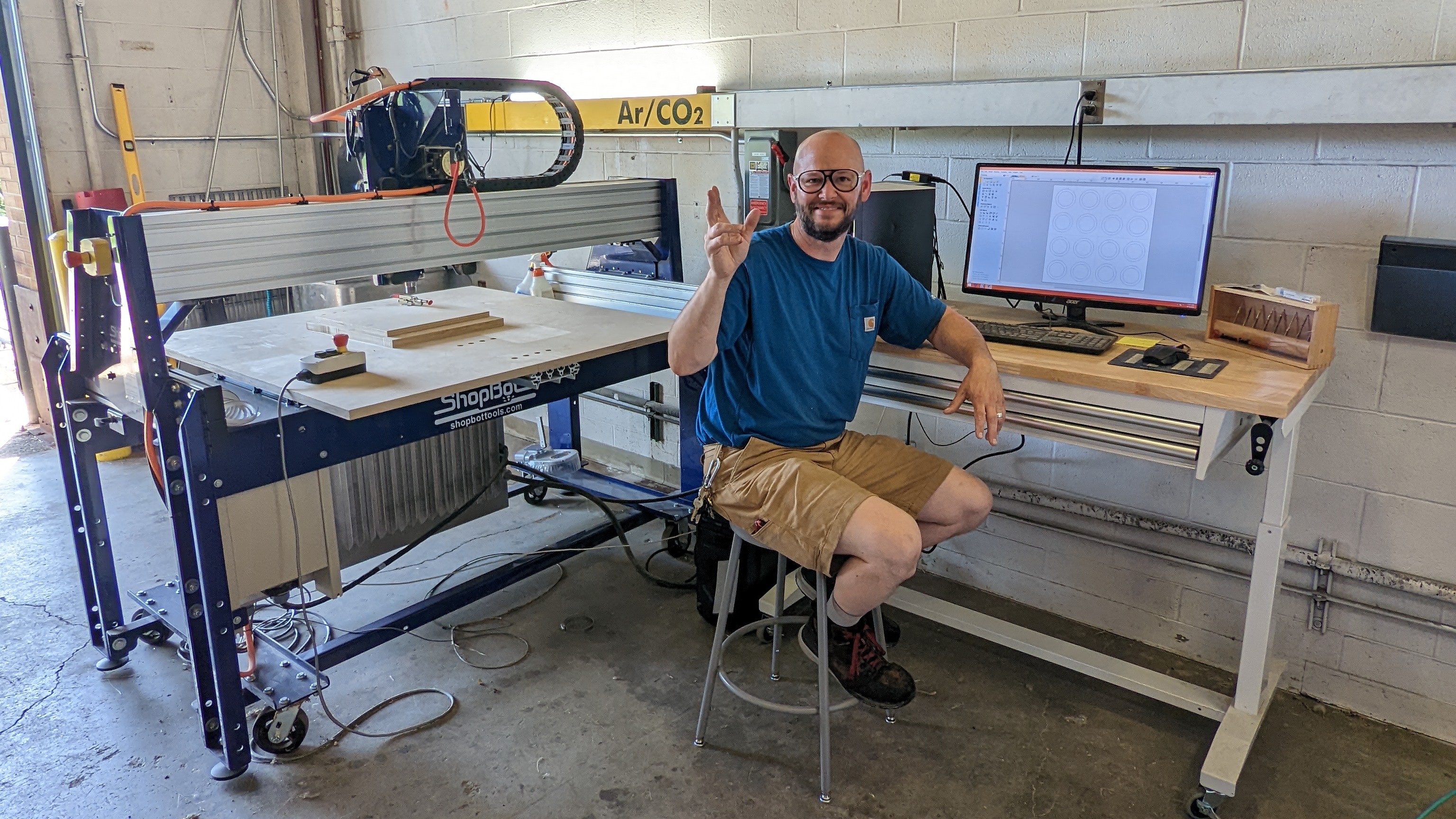

Besides the CNC machines in the Rapid Prototyping Room, the Integrated Studio has an area at the back of the studio where the much larger CNC equipment resides.

The large CNC equipment consists of:

- CNC Shopbot Router

- CNC Koike Pro Shop Plasma Cutter

- 12 inch Precision Miter Saw

- Vertical Band Saw

- Hydraulic Horizontal Band Saw

- Powered Slip Roller

- Powered Tube Roller

- Drill Press and Milling Machine

- 20 inch Disc Sander

- Powered Grinding Wheels

- Oxyacetylene Tanks

- 211 Miller MIG Welder

- (2) 140 Miller MIG Welders

- 300 Continuous MIG Welder

- 250 Miller TIG Welder

- Hand-Held Plasma Cutter

- 5 ft Manual Shear

- 5 ft Manual Box Brake

The second floor contains dedicated studio space for advanced Studio majors as well as a clean lecture space.

Updated: 12/16/2022 05:10PM