Facilities

Training and Educational Facilities

Our training and educational facilities enable a powerful student-centered 21st Century learning environment which is designed to facilitate large group learning activities and student productivity through the use of state-of-art technology.

Architecture & Environmental Design

FEATURES

- Dedicated desk spaces for Grads

- PC workstations

- Smart projectors

- Pin-up walls

- Self-serve plotting

- 3D printing

- 24-hour access

FEATURES

- Dedicated desk spaces for Undergrads

- PC workstations

- Smart projectors

- Pin-up walls

- 24-hour access

Construction Management

FEATURES

- Table Saw

- Band Saw

- Chop Saw

- Sanders

- Drill Press

- Handheld tools

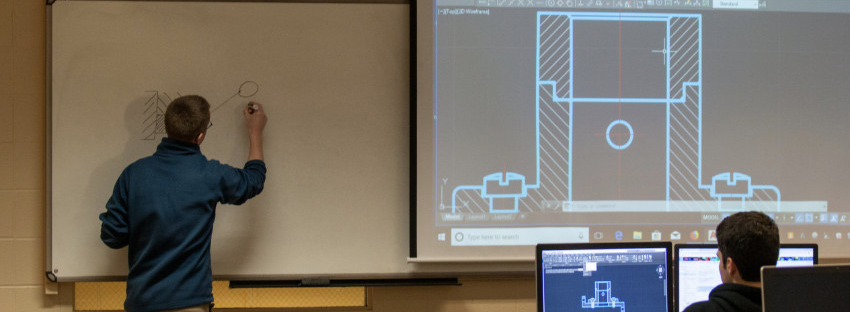

Engineering Technologies

FEATURES

- 8,800 square-foot training complex with classrooms and offices

- 8,000 square-foot hangar

- RedBird Full-Motion Simulator and FRASCA Simulator

- Fleet includes:

- Piper Warrior III - 7

- Piper Archer - 2

- Piper Arrow - 2

- Piper Seminole

- Cessna 152

FEATURES

- 30 student workstations

- 24-hour access

- AutoDesk suite available

- Updated with SolidWorks and Mastercam

- Open to all University students

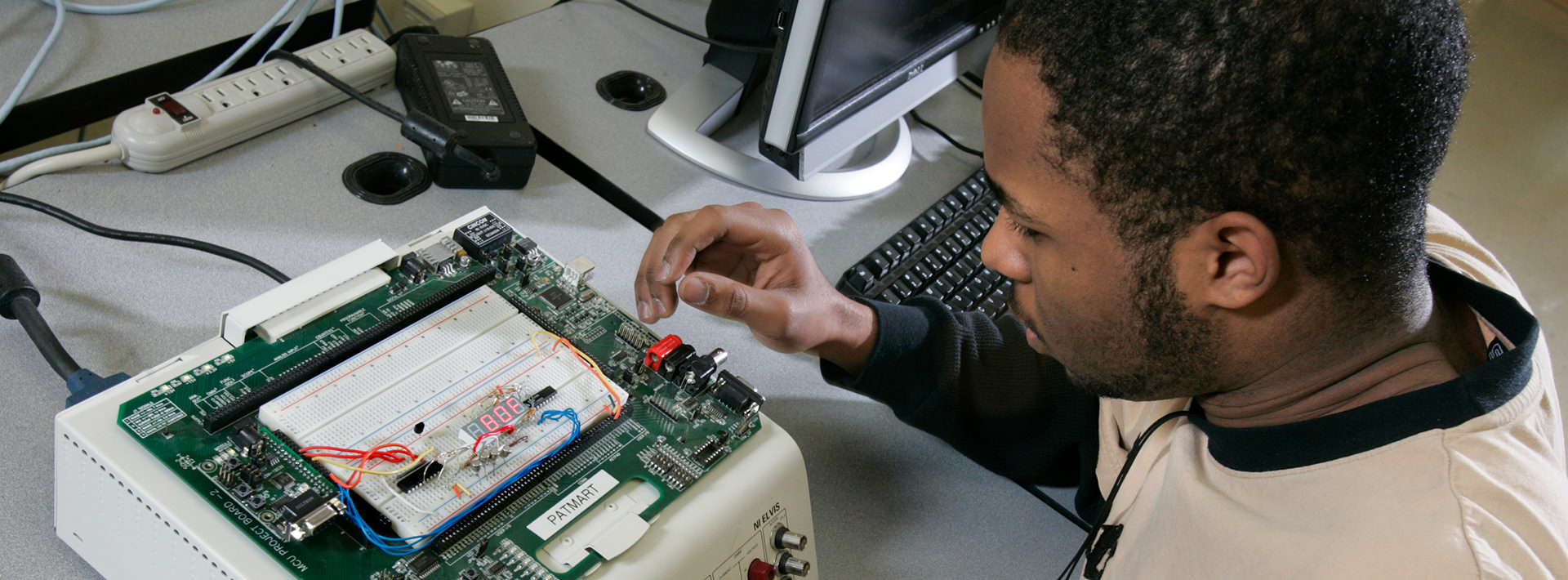

FEATURES

- Instruments and supplies include

- Oscilloscope

- Signal Generator

- Frequency Counter

- Resistors

- Capacitors

- Breadboards

- Soldering Kits

- Multisim software

FEATURES

- Consists of six areas:

- Fluid power

- Metal fabrication

- Casting

- Welding

- Materials properties

- Metrology

- Equipment is available to students working on independent projects

- Instruments and supplies include oscilloscope, signal generator, frequency counter, resistors, capacitors, breadboards, soldering kits, and Multisim software

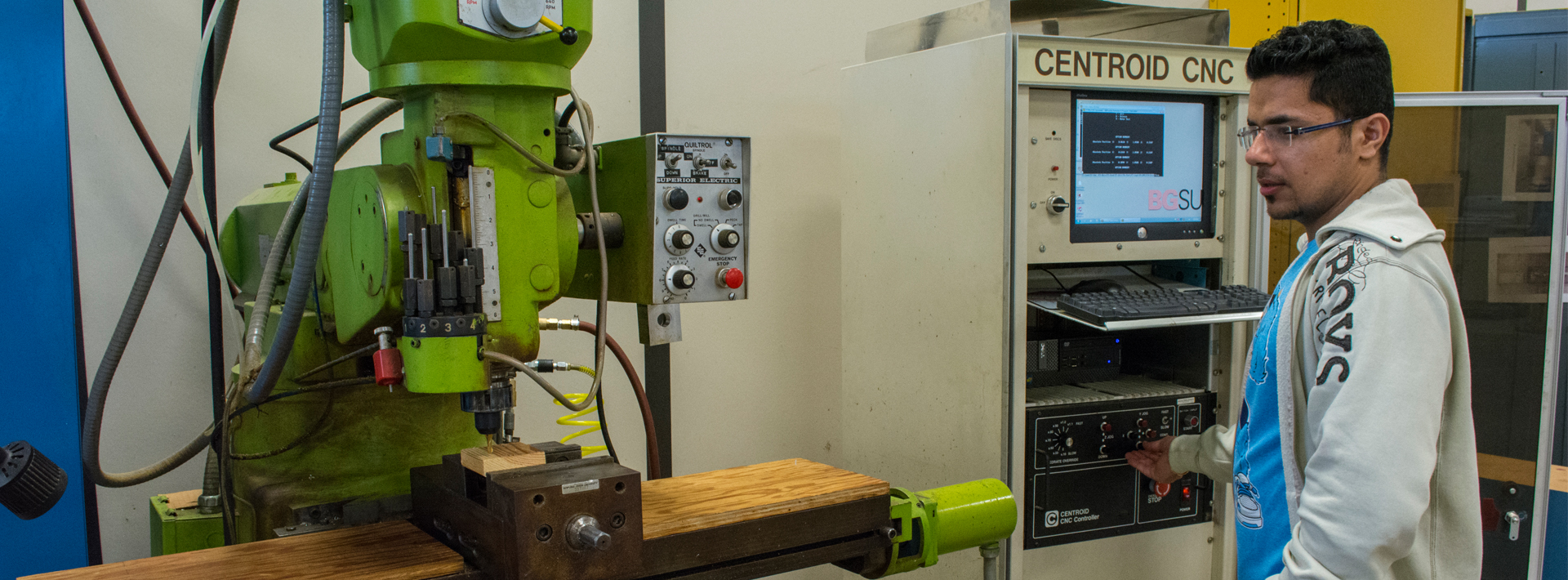

FEATURES

- PLC trainer: 1 Siemens trainer with software and training material

- Computer-integrated manufacturing: 1 CNC integrated with Fanuc robot

- Robotino Mobile Robot: 2 AGVs

- Vision systems: 10 Cognex camera attached to robots with insight software

- Roboguide: 25 seats for Manufacturing Simulation environment

- Automation Studio: 30 seats, Full package

- SCARA Robots: 10 Mitsubishi Robots with programming software

- Teaching Pendants: 10 hand held controllers for Robots

- PLC Automation: 10 integrated control systems with I/O

- Automation Platform: 10 platform with sensors and actuators

- Pneumatic Grippers: 10 integrated hands for assembly operation

- ANSYS, Workbench and Electromagnetic: 50 seats for FEM modeling and simulation

- 20-sim: Unlimited seats for Mechatronics simulation environment

FEATURES

- Ten industrial training robots (SCARA Mitsubishi) integrated with automation and control systems through Ethernet PLCs and CC-link networks.

- Cognex vision systems for quality inspection.

- Electro mechanical and pneumatic Mechatronics systems.

Visual Communication Technology

FEATURES

- Gerber Cutting Table

- EFI Vutek QS2000 Flat bed Ink jet Printer

- Esko ArtiosCAD Software

FEATURES

- 30 Machintosh Work Stations

- Adobe Creative Suite

- Blender

FEATURES

- Westcott Light Modifiers, Reflectors and Continues Lights

- Paul C. Buff strobe lighting equipment

- Variety of backgrounds, table top surfaces and props for portraits and product photography

Updated: 01/17/2024 04:33PM